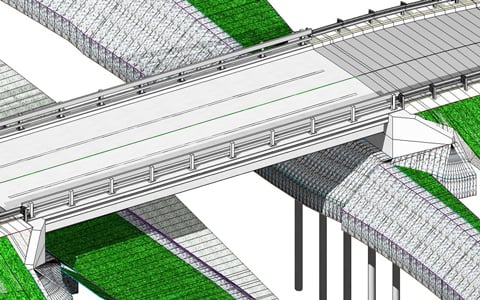

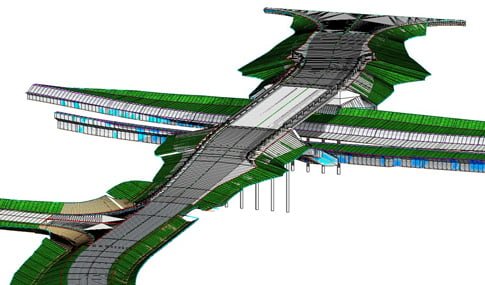

VHB partnered with the Vermont Agency of Transportation (VTrans) to spearhead the agency’s first full utilization of Model-Based Design (MBD) for digital delivery of the new Chester Town Highway Bridge project using the model as the legal document. The technology enhanced design through 3D modeling and allowed the team to communicate significantly more information to construction contractors over traditional two dimensional plans. VHB helped advance the project from preliminary design into final design using MBD to enhance efficiency, accuracy, and collaboration.

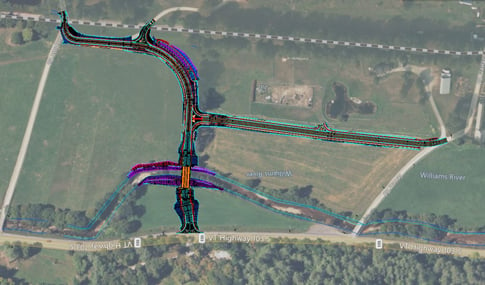

The Chester Town Highway Bridge project consists of removing two existing aging bridges and replacing them with one new bridge over the Williams River in Chester, VT. Early during project scoping, VTrans explored the idea of consolidating the two existing bridges into a single bridge along with construction of 1,800 linear feet of new roadway that would still provide connectivity to state highway VT Route 103. VHB worked with VTrans to identify this as a pilot project for complete digital delivery in which the entire project will be three dimensionally modeled and the model will be used to bid and construct the project.

“Through our close relationship and understanding of the benefits of MBD, VTrans was confident we could utilize this tool and move forward with enhanced digital delivery,” said Aaron Guyette, PE. “MBD is the way of the future for civil engineering, and we’re laying the foundation by training our design teams to deliver technology-enabled solutions."

MBD project development allows project teams to directly manage and control every design detail within the 3D model itself. This means all project team members can easily collaborate, make updates, and quickly access data in a central location, leading to enhanced efficiency and accuracy. The model will also add efficiency for quantity calculations as each element of the model will be assigned meta data that coincides with pay items allowing for automating earthworks calculations, detailed itemized bridge quantities, and reinforcing steel schedules.

“The use of MBD will ultimately make us better engineers and will provide built in quality checks related to the accuracy of the model—inherently benefiting grading/earthworks, structural fit-up, conflict resolution, and utility coordination,” said Aaron.

VHB’s role also included landowner and public coordination, National Environmental Policy Act (NEPA) compliance, and coordination with regulatory agencies, state and federal permitting, highway design, structural design, and three-dimensional modeling. As the project moves into construction VHB will support use of the model in the field by both the construction contractor and VTrans inspectors.

VHB is an AEC leader invested in firmwide MBD training for advanced CAD users. VHB’s MBD Coaches Program promotes digital project delivery for infrastructure projects and received a Bentley Systems’ Going Digital Award in Infrastructure recognition last year. This 12-week advanced training curriculum enables VHBers to become MBD coaches to support the advancement of MBD as a standard for project delivery and integrate technology-enabled concepts into all projects.

For more information about the Chester project, reach out to Aaron Guyette, or learn more about digital project delivery at VHB.