Forward-thinking insights focused on a more sustainable tomorrow.

Mercury Flooring: The Hidden Dangers and Potential Solutions

A focus on the health, safety, and well-being of the public relies on the diligent efforts of local, state, and federal health officials. The far-reaching impacts of their decisions weigh heavily on parents, educators, and citizens—with sensitivity being especially high during the ongoing COVID-19 pandemic. As schools and municipal facilities continue to evolve their safety procedures, and as public life resumes incrementally, all health risks are being extensively assessed and considered.

Closer scrutiny of the issues that affect our overall health have revealed an emerging threat. Mercury-containing synthetic floors commonly used in schools, hospitals, athletic facilities and gyms, and public building multipurpose spaces have potential to pose serious health risks. However, no federal regulations currently exist to mitigate this risk.

Understanding Mercury Flooring

Between the 1960s and 1990s, the manufacture of synthetic, polyurethane flooring met the demand for a resilient, cushioned, non-slip surface. In its liquid form, the material could be poured directly over concrete sub-floors. Within this formula, a mercury-containing catalyst known as phenylmercuric acetate (PMA) produces a seamless, springy surface and was widely installed in school gymnasiums across the country.

Mercury flooring’s durability and usability make it a desirable surface for many purposes—basketball courts, cafeterias, even indoor running tracks. The self-leveling, springy properties of mercury flooring are shock-absorbing. Its solid, seamless final state is also highly customizable and can match virtually any aesthetic. Mercury flooring also stays rubbery for longer and resists water damage, so its resilience and durability has historically made it a desirable choice for many schools and public facilities.

After the 1990s, the use of mercury flooring subsided but has been found in floors manufactured as recently as the early 2000s. It was believed that the mercury within couldn’t escape due to protective coatings of polyurethane. However, schools in New York and New Jersey are at the forefront of discovering that this flooring material may cause more harm than originally thought.

While there are no federal laws or regulations controlling the amount of mercury vapor in homes or schools, agencies like the Agency for Toxic Substances and Disease Registry (ATSDR) recommend certain maximum concentrations at the state and federal level. New Jersey Education Administration (NJEA), in conjunction with New Jersey Work Environment Council (WEC) and the Healthy Schools Now (HSN) Coalition, has released a report citing the hazards contained within mercury flooring. Currently, New York State has banned the use of mercury flooring, along with a handful of other states, including Minnesota.

Determining Risk & Remediation Opportunity

PMA is never gone or diminished but stays within the flooring material. As PMA breaks down over time, it releases mercury vapor. Mercury vapors are heavier than air and tend to remain near the floor surface, in the breathing zone of occupants—it’s this vapor that is the root cause of concern.

In schools across New Jersey, floors installed containing mercury could, decades later, still off-gas mercury in concentrations far exceeding the threshold level established by the NJDOH. Mercury vapor concentrations in air above the established thresholds can present an exposure risk to both children and adults.

Symptoms of mercury exposure can include emotional changes, insomnia, neuromuscular changes, and mental function, in addition to kidney and respiratory failure, which can lead to death.

Not every case is the same, and the overall risk in a situation with elevated mercury concentration is not extremely high, yet no level of risk is appropriate when it comes to safety, especially for children. The colorless, odorless gas can lead to brain and kidney damage when inhaled, and in children, can affect overall development. In addition, continued maintenance or resurfacing of these floors can lead to higher releases of these vapors, also exposing workers to the harmful effects. In some cases, even furniture and equipment can absorb and re-emit this gas.

Offering a Solution

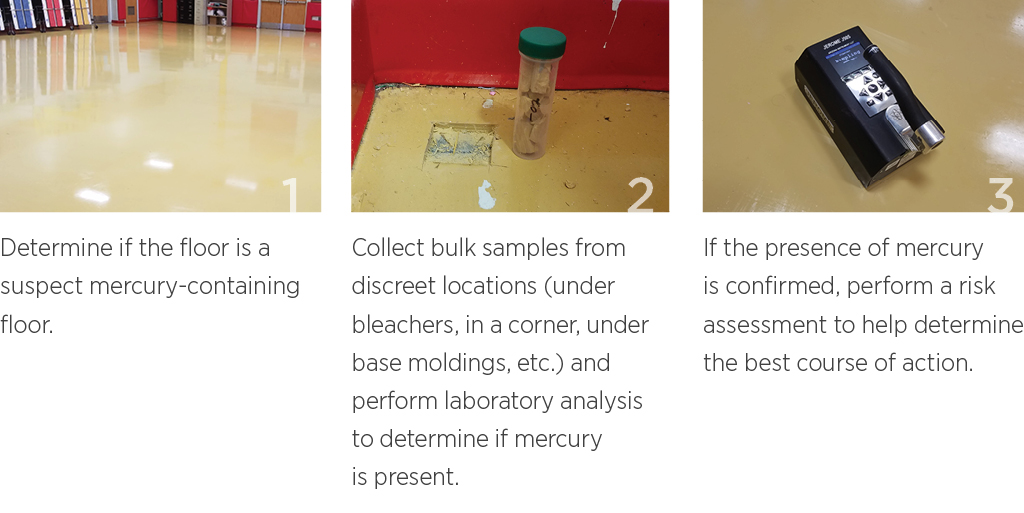

Addressing the hazards mercury flooring presents is a process similar to many hazardous materials, like asbestos. VHB performs a three-step process with technical oversight by an in-house CIH to evaluate the presence of mercury and associated risk.

The CIH evaluates the mercury vapor concentrations in the air to determine if mercury vapor is impacting the indoor environment and what response action should be taken. If the results are within thresholds established by the Department of Health, a solution may be as simple as periodically monitoring the conditions.

If the results exceed established thresholds, the CIH will assist in determining the appropriate solution. Possible corrective actions may include vapor mitigation or abatement of the flooring. The only way to permanently eliminate the risk of mercury hazard is to abate the floor, which involves decontamination processes during abatement and the replacement of the floor with a new surface.

How VHB Can Help

Not all floors have mercury or enough mercury to warrant abatement. Each floor is evaluated individually by the CIH, and those results vary from building to building. While VHB is familiar with the procedures set forth in the New York State and the NJDOH and Occupational Health Surveillance Program’s Evaluation and Management of Mercury-Containing Floors in New Jersey, we understand that this is an emerging issue and follow new technical guidance as it becomes available in other parts of the United States. While there are no federal regulations preventing the use of mercury in flooring, VHB can provide the environmental consulting, design, and oversight services to help navigate this complex and evolving issue and make the best decisions for your facility.

VHB also brings the value of having a qualified team with the experience needed to perform risk assessments and develop sound scientific and practical solutions on a case-by-case basis. The need for a CIH and Certified Indoor Environmental Consultant (CIEC) narrows down the credentials required on these projects to only a localized handful of teams, including VHB. The rare combination of a CIH and a CIEC on our team, and our relationships with abatement contractors allows us to meet state agency qualifications and precedents that have informed how evaluation and remediation needs to happen, despite the lack of current federal regulations.

VHB brings the ideal combination of technical experience and project management of an abatement project, should one be necessary. With 30 years of experience working with schools throughout New Jersey and New York, which are on the frontlines of this issue, we are on the forefront of understanding the depth of use of mercury flooring in schools and public buildings, as well as how to mitigate.

Is your school or municipal facility faced with challenges resulting from mercury flooring? Contact Chris Glowacki today to begin analysis, remediation, and abatement—and planning for a safer tomorrow.